Mantle is launching a new series of $350,000 machines that can 3D-print the mold inserts that are used to produce injection-mold plastics. It’s hard to overstate how important this will be — I caught up with the company’s founders to find out how and why this tech is going to put a serious dent in the speed-to-market for manufacturing.

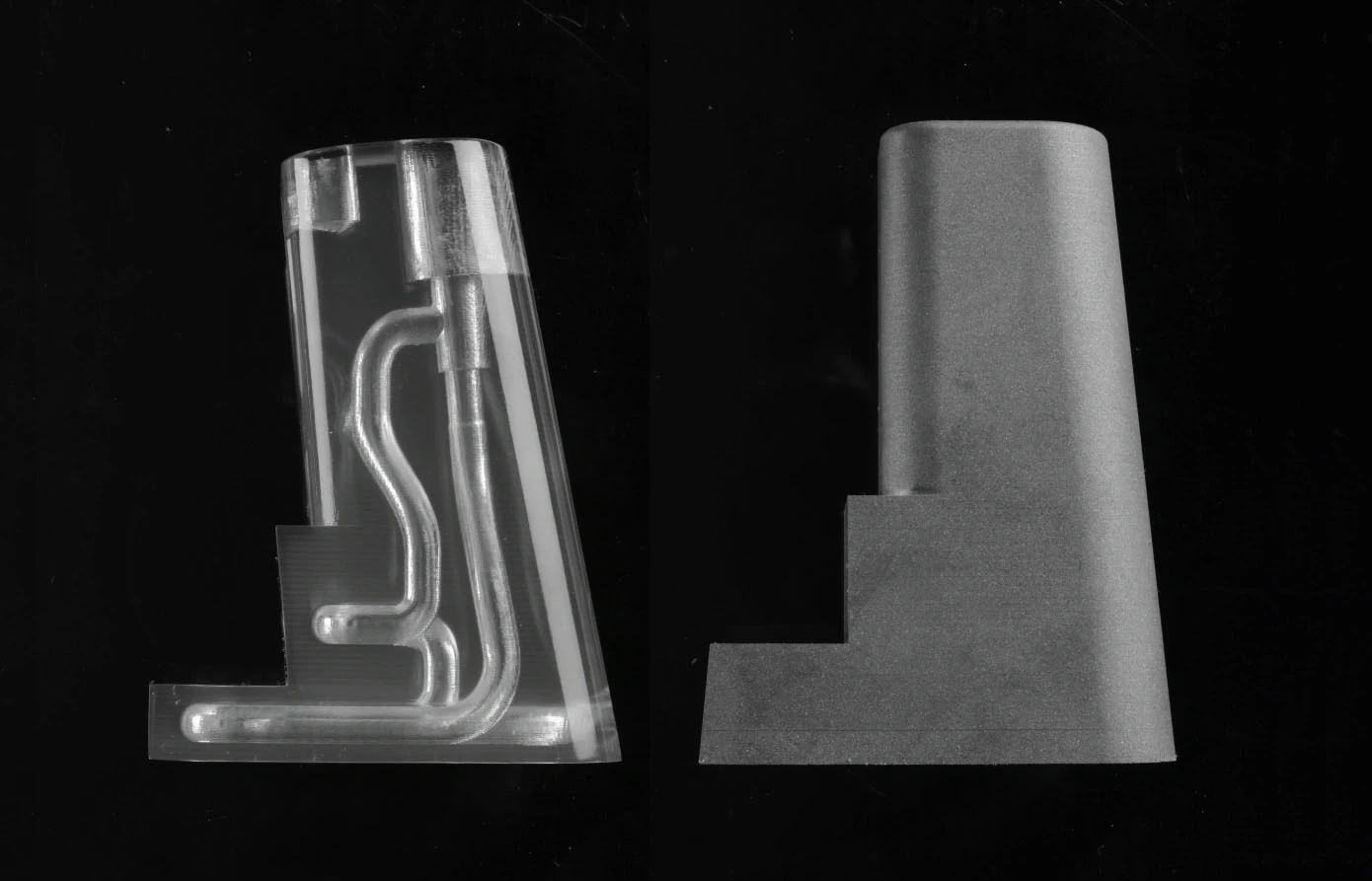

Okay, let’s go deeply geeky for a moment, and take a look at one of the most interesting uses of 3D printing I’ve seen in a long while. To understand why this matters so much, you need to understand how manufacturing works; specifically, how injection molding works. Most plastic parts can be made by the hundreds of thousands, by injecting liquid plastic goo into a mold. This mold typically has water-cooling lines running through it, to bring down the temperature of the liquid, molten plastic quickly, so it solidifies. The mold opens, the plastic part is ejected, and you can go to the next cycle. Almost every small (and many large) plastic parts are made this way. The tools are usually made of extra hard “tool steel,” which needs to be extremely precise. The surface of this steel mold can be anything — smooth, textured, you name it — and anything that’s part of the mold cavity becomes part of the final plastic part. As you might imagine, creating these steel molds is extremely precise work, and it takes a long time (years) to become a tool maker. To become a truly excellent tool maker is a lifelong profession, at least as much art and experience as it is technology.

. . .